The TLC is a firewood processor that has been on the market since the 1990s, appreciated worldwide for the construction, mechanical and technological features. It is a very versatile, automatic cutting and splitting combined system, which guarantees high performance with a single operator. Models: TLC 1000 – 1100 – 1200 – 1300

TLC

from 1000 to 1300 mm

Cutting disc diameter

from 400 to 510 mm

Maximum log diameter

22 – 45 kW

Electric engine power

PEZZOLATO TLC

The updated version of the TLC was presented to the market in 2024. A machine that, since the beginning more than 25 years ago, has won over customers around the world with its winning features: a high-performance combined cutting and splitting equipment for the production of firewood, which can be easily operated by a single operator.

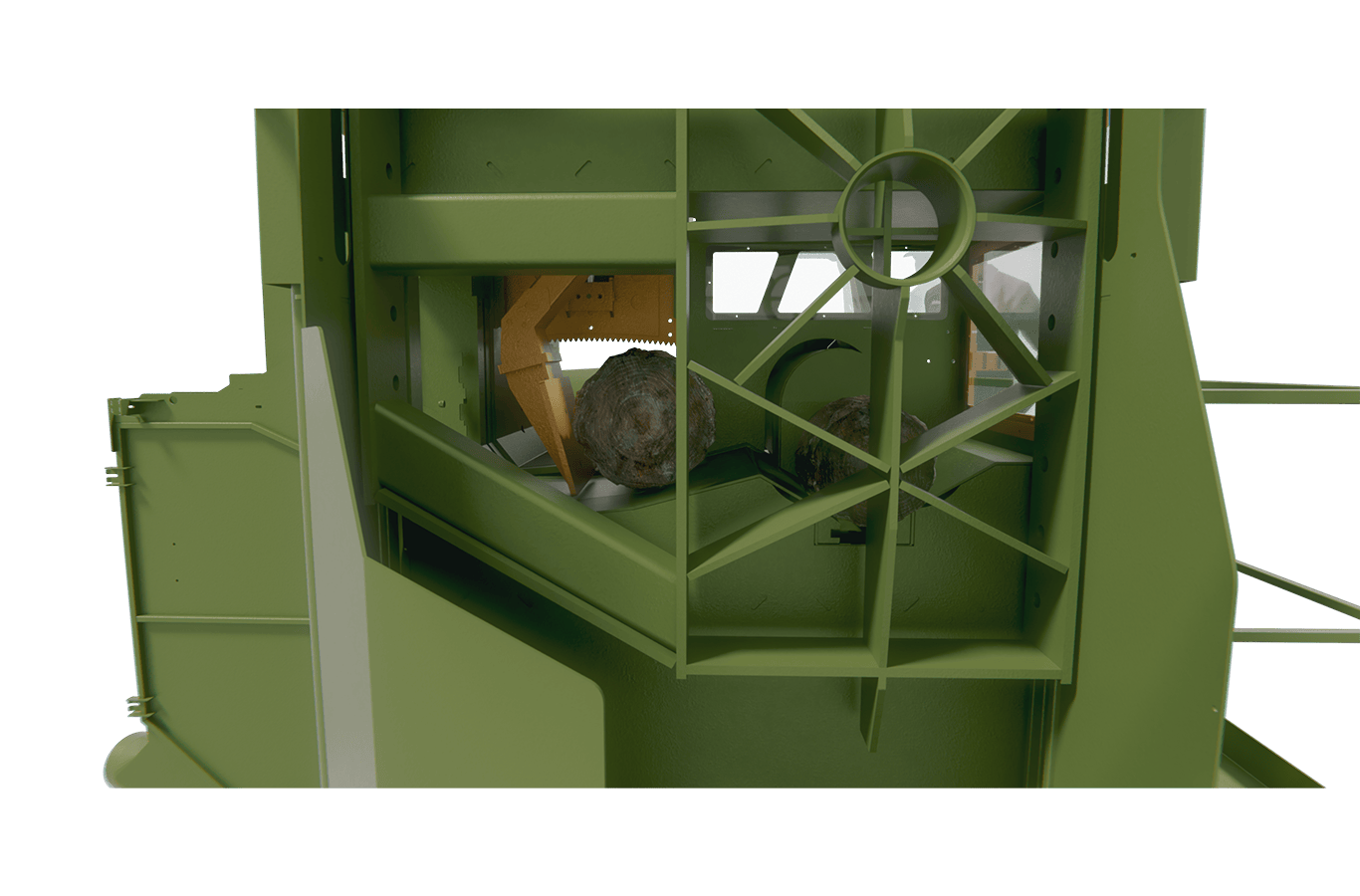

The new TLC maintains its strengths unchanged, such as the versatility to operate both ‘log to log’ and with ‘mixed’ bundles of wood; the cutting unit with side disc saw capable of reducing consumption, conveying sawdust in a natural and dispersion-free way, allowing good access to the log after cutting, and facilitating a better visibility by the single operator; the presence of a rear pusher, fundamental for advancing the material towards the cutting station and for calculating the exact dimensions of the log (or bundle) in order to minimise any waste.

However, the new version presents also important innovations which are the result of the unceasing collection of our customers’ feedback, of our continuous investment in research and development, and of the integration of increasingly high-performance hydraulic and electrical technologies.

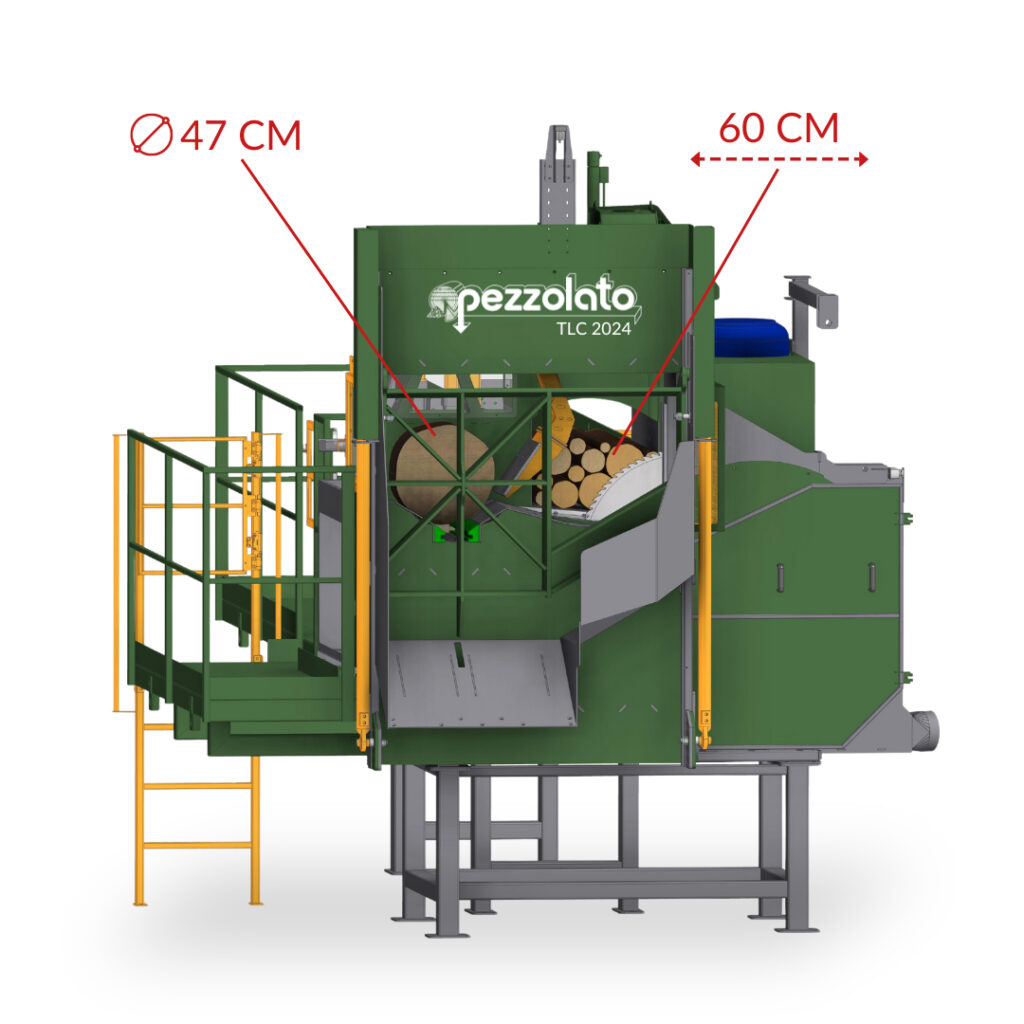

TLC 2024 can operate with cutting discs with a diameter of 1.000, 1.100, 1.200 or 1.300 mm, thus processing logs with a diameter of up to 51 cm.

The new version of the TLC presents also an extended cradle to 60 cm for feeding the cutting station. The extended cradle enables optimised loading of the machine when processing single/short logs, or large bundles of smaller logs. This solution is increasingly appreciated by firewood producers, who are faced with frequent changes in the diameter of the incoming material.

Last, but not least, the hydraulic translator for moving the cut logs towards the splitting station. This solution, previously powered by compressed air, reduces investment and energy consumption for the final user and eliminates any slowdowns related to the temperature of the compressed air, in case of large temperature fluctuations.

The integrated splitting unit is designed to obtain the maximum output when working log by log with a single operator. By simply excluding the splitting grid, these machines can also process smaller log bundles that do not need to be split. By choosing the automatic working cycle, the splitting grid is automatically positioned according to the diameter of the log to be split.

Data sheet

| Maximum log diameter | mm | 400-440-470-510 |

| Feeding channel width | mm | 600 |

| Maximum log passage | mm | from 3400 to 6800 |

| Electric engine power | kW | 22-30 |

| Cutting disc diameter | mm | 1000-1100-1200-1300 |

| Splitting force | ton | 20-27-32 |

| Log splitter passage | mm | 600-1050 |